Here are ten key possible reasons for the failure of Lean production, Operational Excellence (or whatever you want to call it) implementation in Europe:

- Cultural Resistance: Deep-rooted work cultures and hierarchical structures in Europe often resist the continuous improvement and employee-driven change that Lean requires.

- Misinterpretation as a Cost-Cutting Tool: Lean is frequently misunderstood as merely a cost-reduction strategy rather than a comprehensive system for adding value and improving processes.

- Lack of Management Commitment: Insufficient leadership support and understanding of Lean principles lead to weak and inconsistent implementation efforts.

- Inadequate Training and Employee Engagement: Many European companies fail to provide the necessary training and fail to involve employees effectively in Lean initiatives, leading to poor execution.

- Short-Term Focus: A focus on short-term gains rather than long-term cultural transformation can undermine the sustainability of Lean practices.

- Poor Adaptation to Local Contexts: Directly importing Lean practices from Japan without adapting them to fit European industrial and cultural contexts often leads to failure.

- Inconsistent Application Across the Organization: Lean requires a holistic approach, but many organizations apply it selectively or inconsistently, reducing its overall effectiveness.

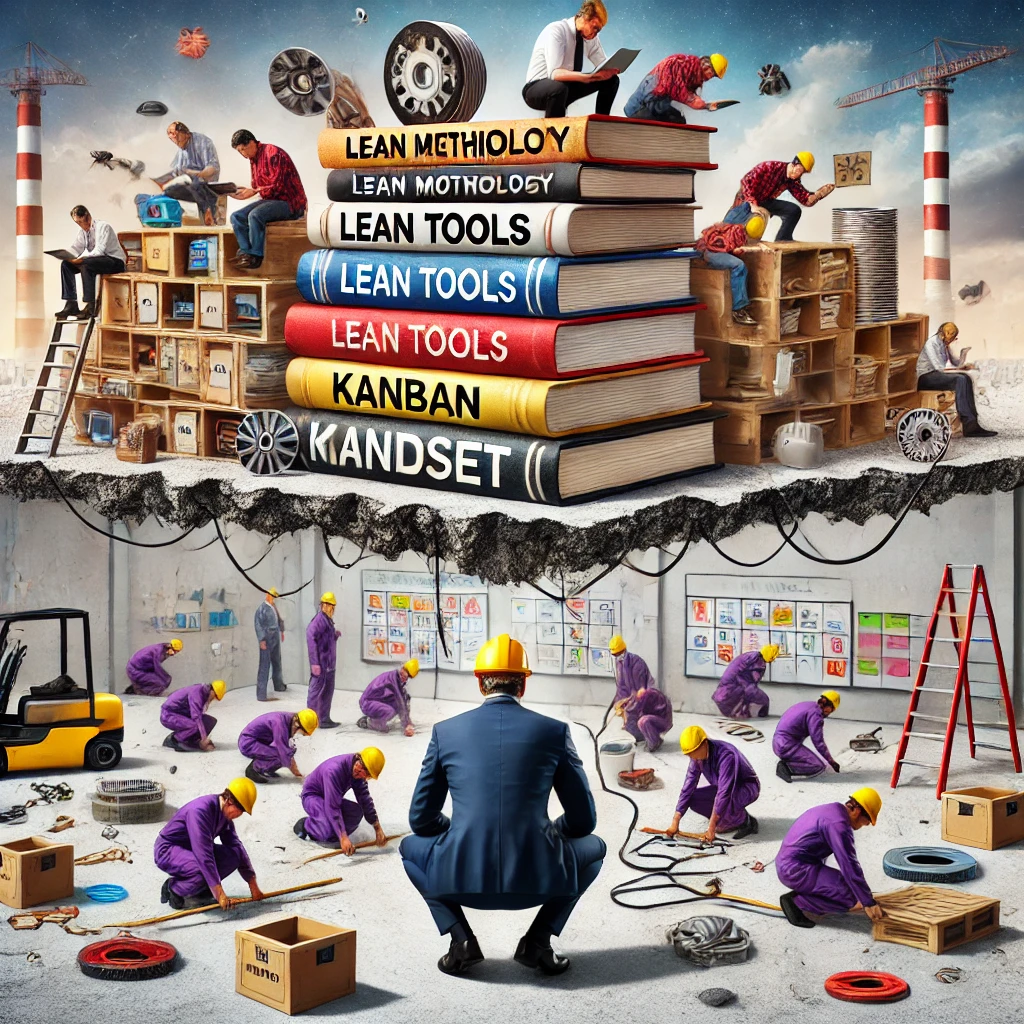

- Overemphasis on Tools over Philosophy: Focusing too much on Lean tools (e.g., 5S, kanban) rather than the underlying Lean philosophy and principles can result in superficial implementation.

- Failure to Address Employee Concerns: Lean changes often generate fears about job security or increased workloads, and companies that fail to address these concerns face resistance.

- Inadequate Measurement and Feedback: Without proper metrics and feedback loops to measure the success of Lean initiatives, it becomes difficult to sustain momentum and make necessary adjustments.

Notional implementation of lean production

A big mistake some leaders do is focusing on Lean methodology and book knowledge instead of building the right mindset, which is crucial for effective Lean implementation.

Those who have been fortunate enough to practice and implement lean production in Japan or South Korea know that most of the energy should be directed towards creating the right mindset based on: respect for people at all levels, mutual trust, fairness, communication and transparency.